Monitoring multiple services with one eGauge meter

Overview

It's common to find sites with large stepdown transformers (e.g. to convert a 277/480V service to 120/208V for lighting or receptacle loads). To measure any AC load, the eGauge requires a combination of voltage references (Lx voltage terminals) and amperage references (CTs). It's not possible to measure loads on both the primary and secondary side of a transformer by simply scaling the voltage reference from either the primary or secondary side, because large transformers typically introduce an unknown and dynamic (varying in a non-linear relationship based on load profile) degree of phase shift between the primary and secondary side of the transformer. Until recently, the only option to accurately measure power in this scenario was to either use multiple eGauge meters (one with voltage references tapped on the secondary side of the transformer and one with voltage references tapped on the primary side of the transformer).

Using the ESH044 Sensor Hub and at least one EV1000 High Voltage Sensor (the number required will depend on the service type), it is possible to obtain voltage references from multiple services simultaneously. Note that each EV1000 sensor uses a port on the eGauge, so there are still limitations (any combination of CTs and EV1000 sensors, up to 15 or 30 depending on the eGauge meter model). An ESH044 Sensor Hub must be used - one sensor hub can support any combination of EV1000 sensors and CTs (up to four total devices per hub).

This guide only applies to EG4xxx meters. Older EG30xx and eGauge2 meters do not support the EV1000.

Installation Considerations

Typically, there are a few general rules to follow when monitoring multiple services:

1. The service with the lowest voltage should be connected directly to the eGauge, and the higher voltage service(s) should be monitored with the EV1000s. The eGauge can support a phase to neutral voltage of 277Vrms, while the EV1000 can support a voltage of up to 707Vac/1000Vdc, meaning the EV1000 is much more flexible than the meter itself.

2. Sensor Hubs must be powered. Up to 2 hubs can be powered directly from the eGauge via the USB ports on the meter. For installations where more hubs are required or the USB ports are in use (e.g., for Modbus RTU communication) the hubs can be powered directly from a generic 5Vdc power supply or a USB hub may be used.

3. All hardware must be installed in a suitably rated enclosure. eGauge Systems offers several powered enclosure kits which are suitable for this purpose. Most kits feature DIN rails (for mounting the eGauge meter and EV1000s securely) along with a powered receptacle and optional stepdown transformer (which can be used to power the 5Vdc supply for the sensor hubs and/or other supporting hardware).

Examples

The following are general examples which may be useful for planning a specific installation. Note that these examples may omit certain details (for example, not all ports are shown on the eGauge meter). These are intended to serve as guidelines only - always consult local code requirements when planning an installation.

Hardware appearance in the following diagrams may not reflect the actual size or layout of actual hardware. Refer to the product pages for actual measurements.

Configuration examples are correct for the diagram shown. Note that it is essential to associate CTs with the correct phase, and failure to do so will result in incorrect readings. Correct phasing can only be guaranteed using a multimeter to verify phasing.

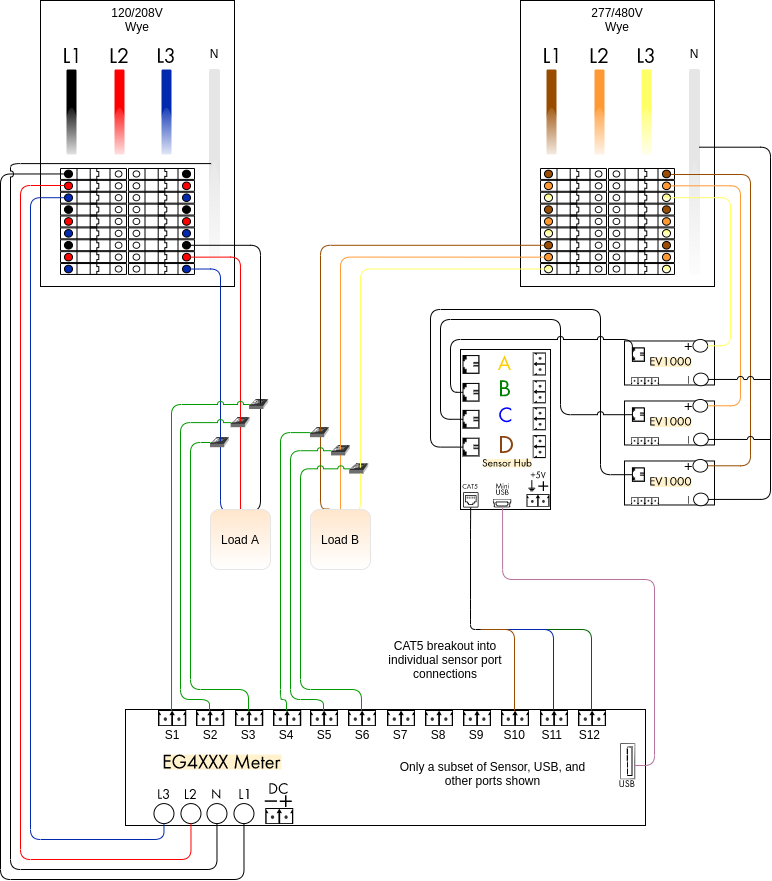

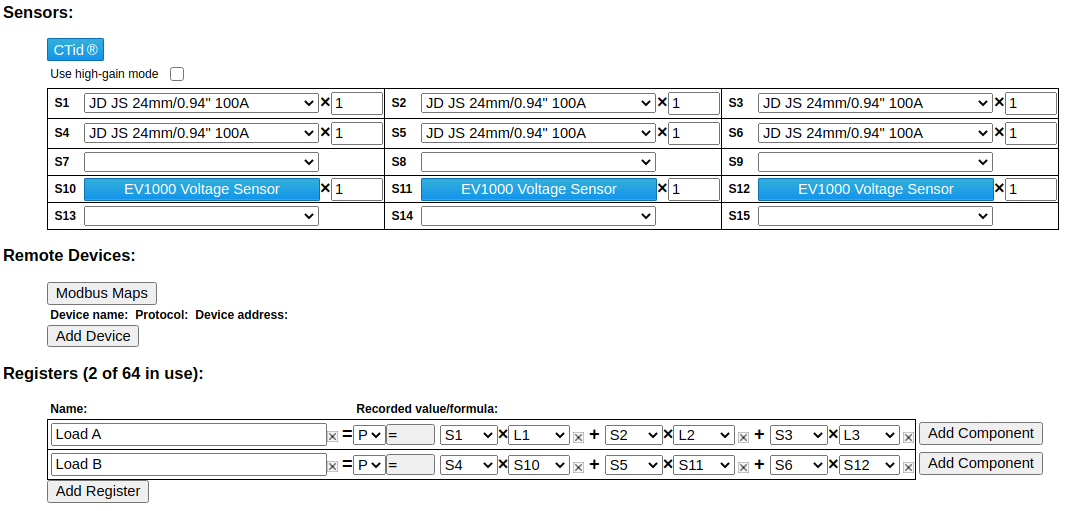

277/480V Wye and 120/208V Wye

In the following example, the eGauge is monitoring two loads - one on a 120/208V service, and one on a 277/480V service. Note that the neutral to loads A and B are not shown.

The meter configuration would be set as follows (note that the CT selection is filler - use the correct CTs for the actual installation):

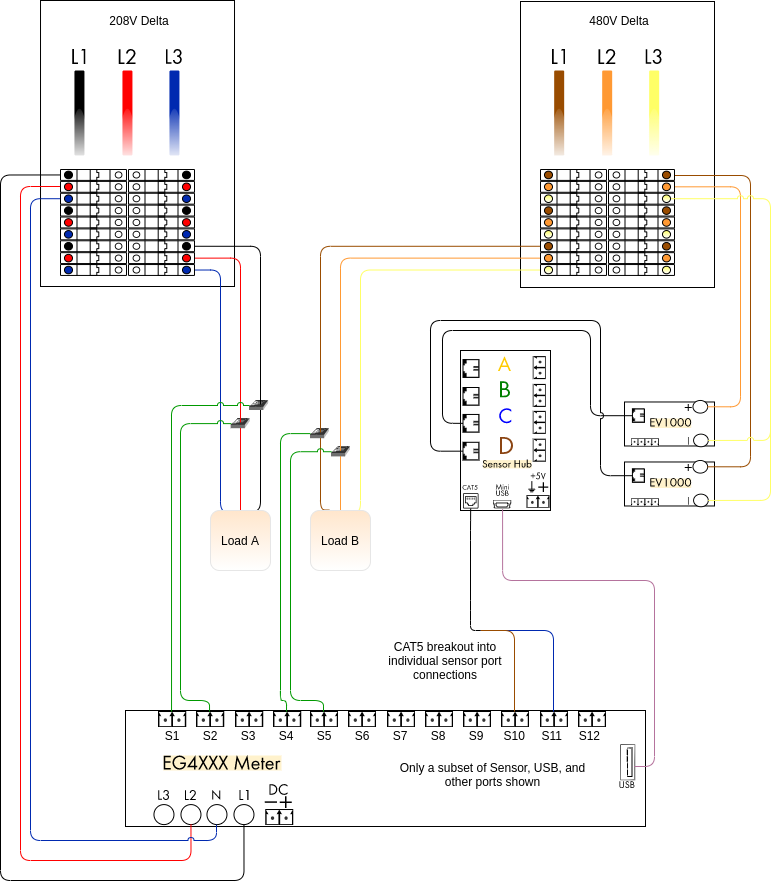

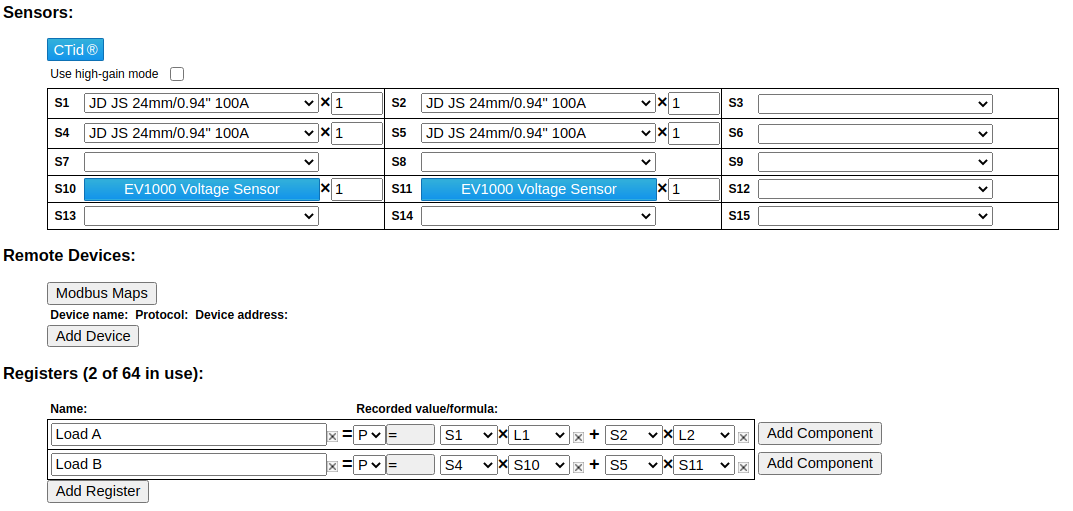

480V Delta and 208V Delta

In the following example, the eGauge is monitoring two loads - one on a 208V Delta service, and one on a 480V Delta service. Since no neutral is present, one phase on each service is effectively treated as a neutral - for the 208V service, C phase is connected to the N terminal, and for the 480V service, C phase is connected to the negative (-) terminals on the EV1000s.

In this configuration, only two CTs are required - one on each phase which is not connected to the N or (-) terminal.

480V delta services cannot be connected directly to the eGauge! Doing so will damage or destroy the meter. EV1000 sensors or stepdown transformers must be used to monitor a 480V delta service.

The meter configuration would be set as follows (note that the CT selection is filler - use the correct CTs for the actual installation). Again, for delta services only two CTs per three phase load are required: