Logging data from pulse meters

This article describes using pulse sensors to read from energy meters, but any meter such as flow meters may be used. The only difference is to change the formula register from "Power [W]" to the particular measurement and using a "constant" that represents 1 unit (per pulse) of that measured item, for example cubic meters if volumetric flow. If the eGauge does not support the measured item, "number with 3 decimals" may be used instead.

The eGauge Pulse Sensor (EPS) can be used to monitor a dry contact pulse output from many different types of devices, including energy meters equipped with a KY (2-wire) or KYZ (3-wire) pulse output, sometimes referred to as Form A or Form C, respectively. Using pulse to monitor power and energy values results in less-granular data than using physical voltage references and CT amperage readings, due to the fact pulse meters only indicate when one or more cumulative energy units (e.g., 1 kWh or 50 Wh) have been used.

Physical Connection

KY and KYZ pulse outputs designate "K" as "common" which is always used in KY or KYZ applications. The eGauge Pulse Sensor (EPS) is a "KY" connected sensor. The "K" (common) should go to the EPS ⏚ (ground) terminal, and either Y or Z to the SIG (signal) terminal.

KY (2-wire) vs KYZ (3-wire)

In simple terms, if "Y" is closed, "Z" is open. If "Z" is closed, "Y" is open. Therefore, only Y or Z (in conjunction with "K") is needed to detect pulses. The eGauge Pulse Sensor (EPS) is a 2-wire KY style sensor, so either the Y or Z wire is used and does not matter which.

Net Metering (consumption and generation)

KY and KYZ pulse outputs can only indicate the increase (and not decrease) of a single reading. For example, if a net meter is able to spin both directions (one direction for utility draw, and the opposite for back-feeding to the utility), a single KY or KYZ output is not able to represent both directions, as pulse values only change from closed to open, and open to closed, not indicating which direction (draw or back-feed) it is for. Thus, with bidirectional power, there should be 2 independent KY or KYZ pulse outputs, requiring two EPS sensors, one for utility draw and another for back-fed power to the utility.

Configuration

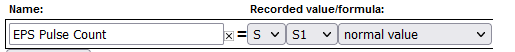

- Using CTid, configure the sensor input and create a register for the pulse count, where "S1" is the sensor input the EPS is connected:

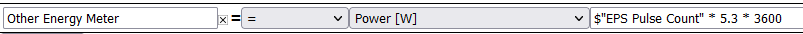

- Create a power formula register to calculate the power reading from the pulse count. The formula register contents should be:

$"Pulse Register" * constant * 3600wherePulse Registeris the register name of the register recording the pulse count, andconstantis the meter Wh constant factor (effectively, in watt-hours what one pulse indicates or "Wh-per-pulse"). The below screenshot shows the calculation for a single pulse representing 5.3 watt-hours:

Math behind the formula register

The reason 3,600 is multiplied by the Wh-per-pulse is due to the meter reading data at second-granularity and there being 3,600 seconds in one hour. For example, if there is a meter constant of "1" (meaning 1 pulse is 1 Wh), when the eGauge meter receives 1 pulse, it will record "1" at that second in time, which will show as 1 watt during that 1 second it was detected (1 watt-second of energy). To convert watt-seconds to watt-hours, we multiply by 3,600 seconds.

If a single pulse represents kWh rather than Wh, the formula will need to be multiplied by 1,000, such as:

$"Pulse Register" * constant * 3600 * 1000

Miscellaneous Notes

Pulse meters change output state each pulse; that is, the output goes from open to closed to indicate a single pulse, than open to closed to indicate the next pulse, and alternates continously for each pulse. If testing the pulse sensor and recorded data by shorting the SIG and GROUND terminals, contacting will result in 1 pulse, and releasing will result in an additional pulse.